SOFTWARE

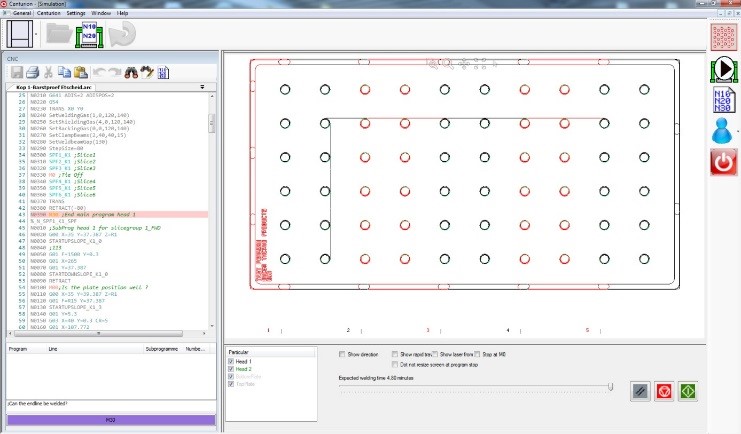

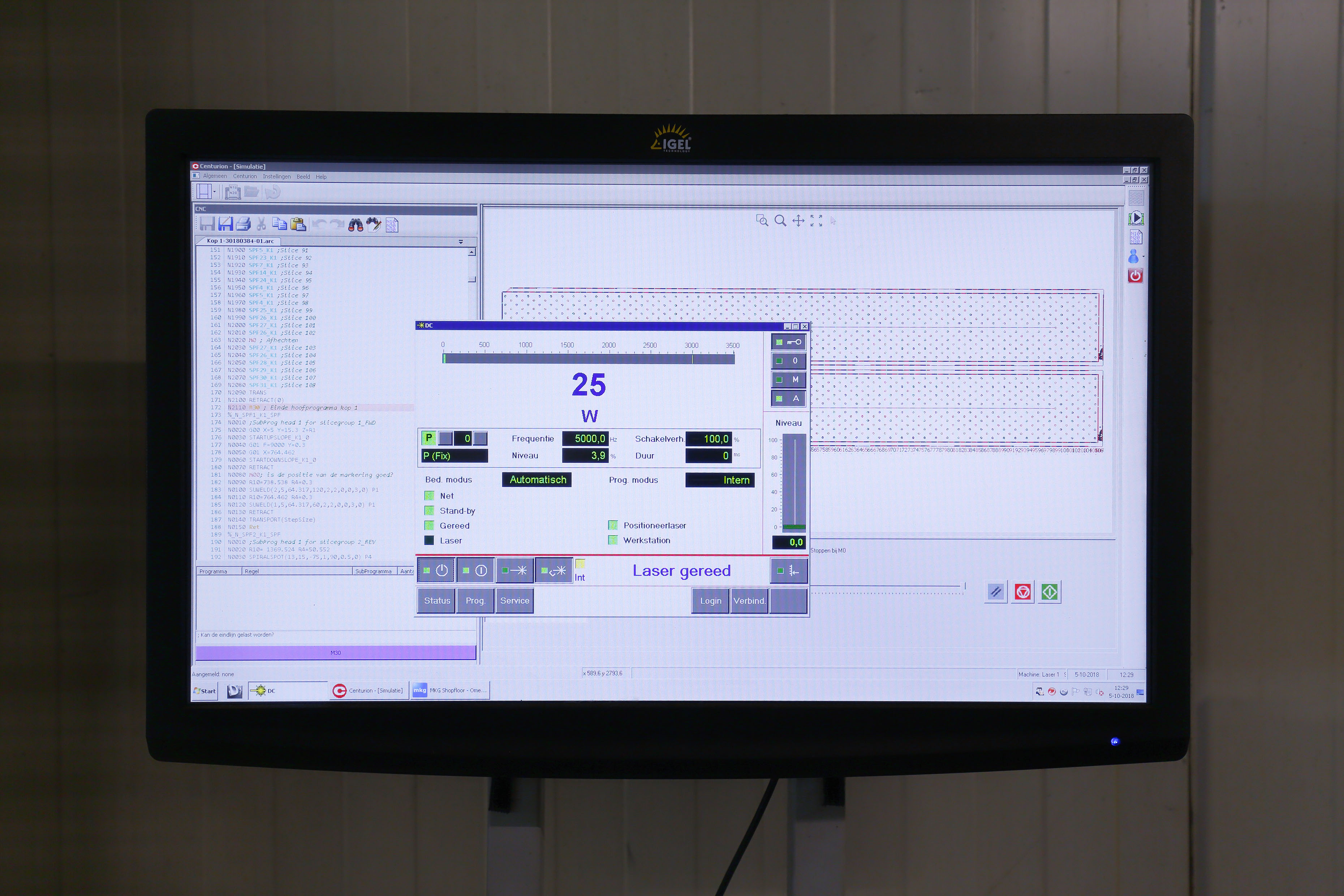

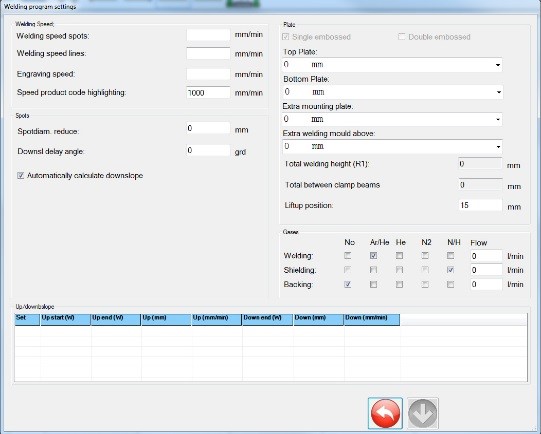

Omega has developed dedicated Quadra Clamp Software to translate DXF-files from AutoCAD welding pattern drawings to Siemens CNC codes. The software is in English language and Windows oriented with all its user-friendly advantages.

In 2020 we started with a major update where the program was completely re-written in the latest software language and all user comments and wishes were incorporated.

This software gives you the oppertunity to make even relatively complex heat-exchanger designs and to generate the CMC program belonging to it in a very short time. It also calculates the theoretical welding time.

The software also supports to split the total pattern between welding head A and welding head B in case a second welding head is installed.

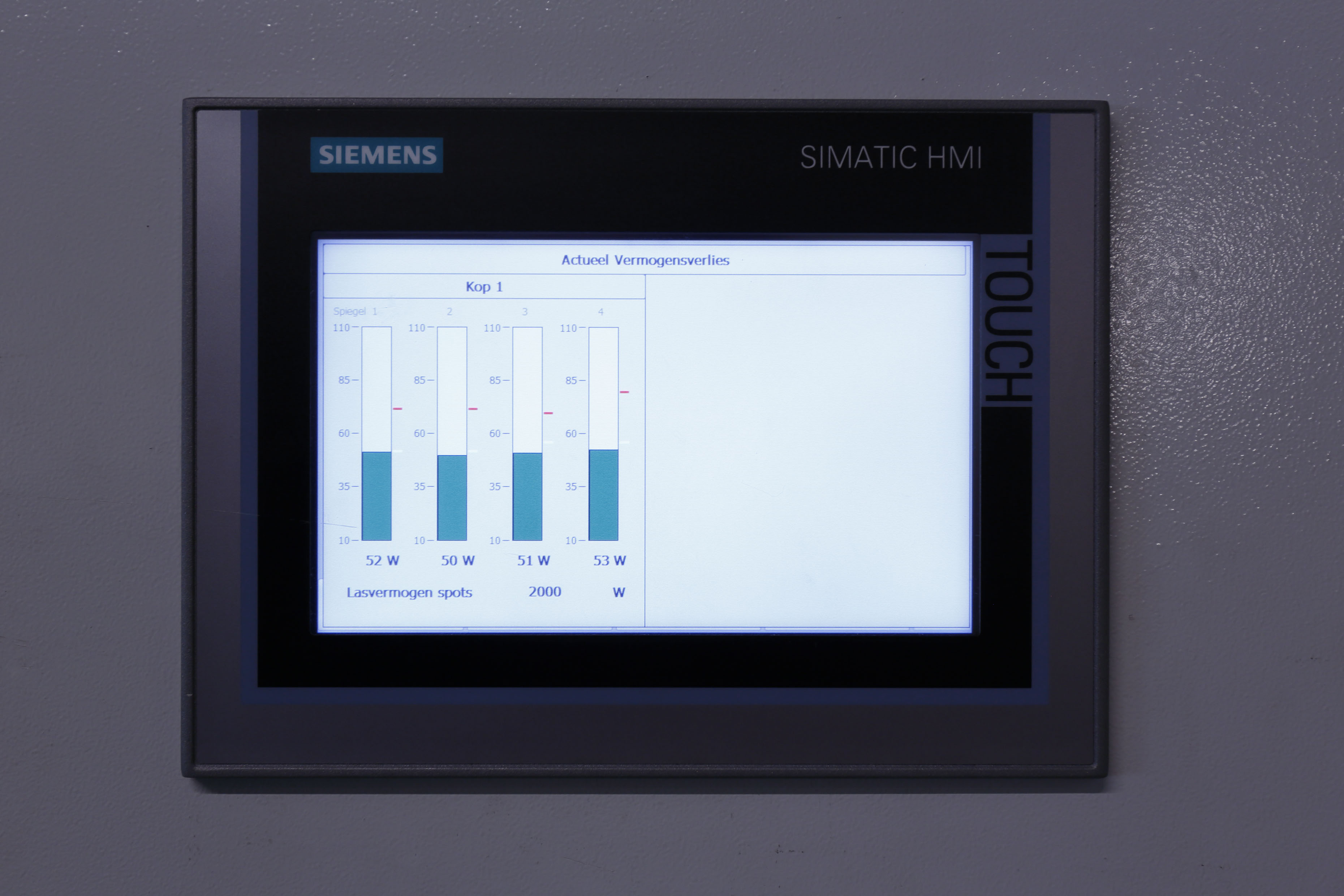

Power Loss

The Omega Quadra Clamp is equipped with a Power Loss System to monitor the state of each of the external mirrors. These mirrors are water-cooled and the power absorption of each of these mirrors is monitored in real time. When the absorption reaches above a pre-determined value the machine will stop automatically and indicate which of the mirrors has to be cleaned. With this system the cleaning interval can dramatically be reduced resulting in a optics life time of up to 3 years (depending on the welding settings, materials and the operator).

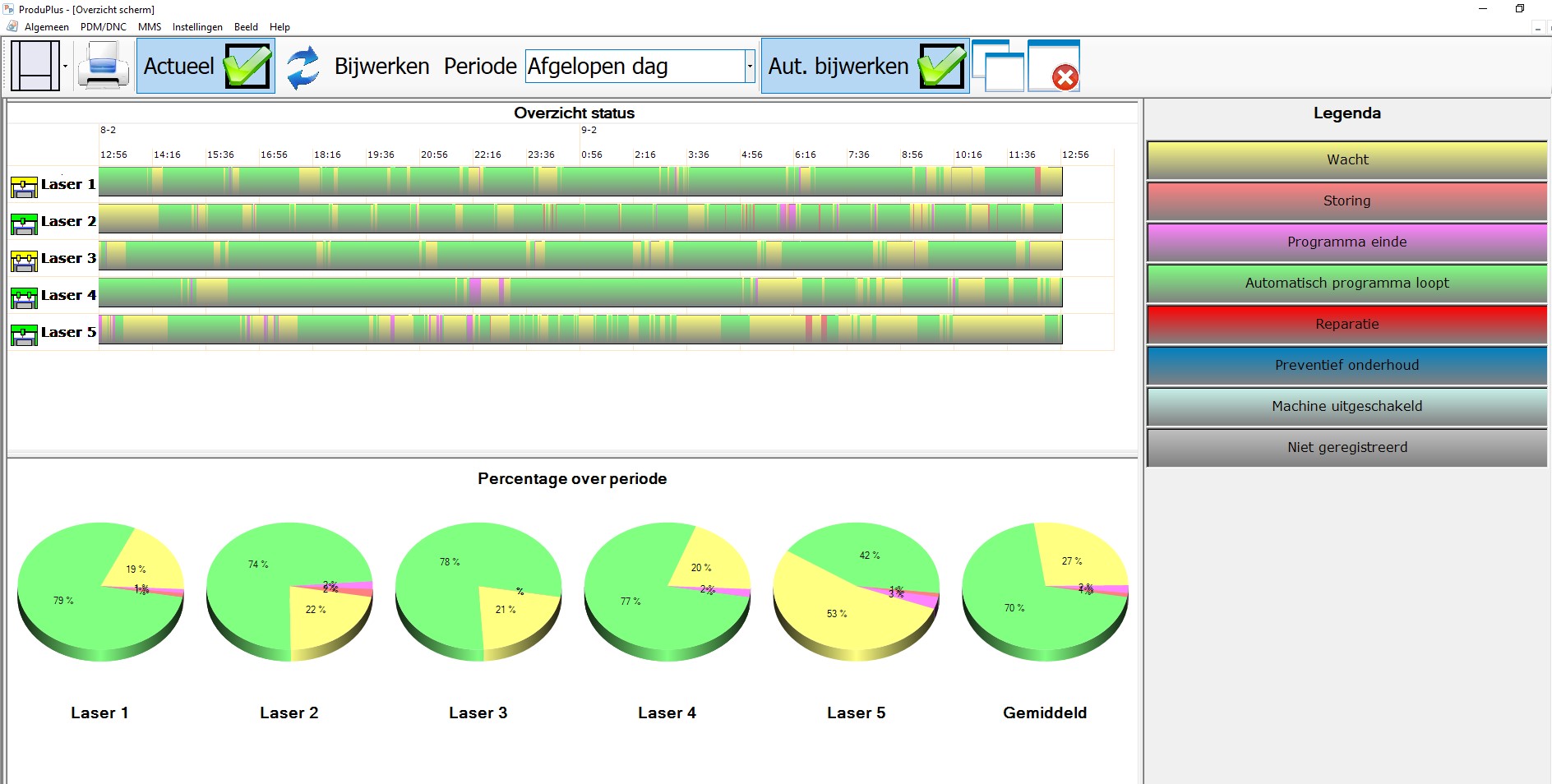

ProduPlus (Smart Factory/Industry 4.0)

Omega can supply and integrate the ProduPlus software as an option. This machine monitoring system that can be used to monitor the status of the welding system in real time.

ProduPlus automatically registers the status of the connected machines and production lines. In the latest version, it makes use of the Simatic HMI of the Power Loss System for operator input about the reason of production loss.

ProduPlus is seamlessly intergrated with the Centurion software for easy access to production data.

ProduPlus is not limited to the Omega welding machines but can be linked to almost all machines and the status is immediately visible.

Omega Laser Systems uses ProduPlus and can demonstrate the advantages.